When one of his client’s turbine-driven generators breaks down, Scott Bresney, an engineer with AGT Services, an Amsterdam, New York-based company that provides generator service for power plants, turns to Broadalbin Manufacturing Corporation in Broadalbin. He sends over a blueprint and requests that the company fabricate the part as quickly as possible. “When a company is down, they lose hundreds of thousands of dollars per day,” Bresney said.

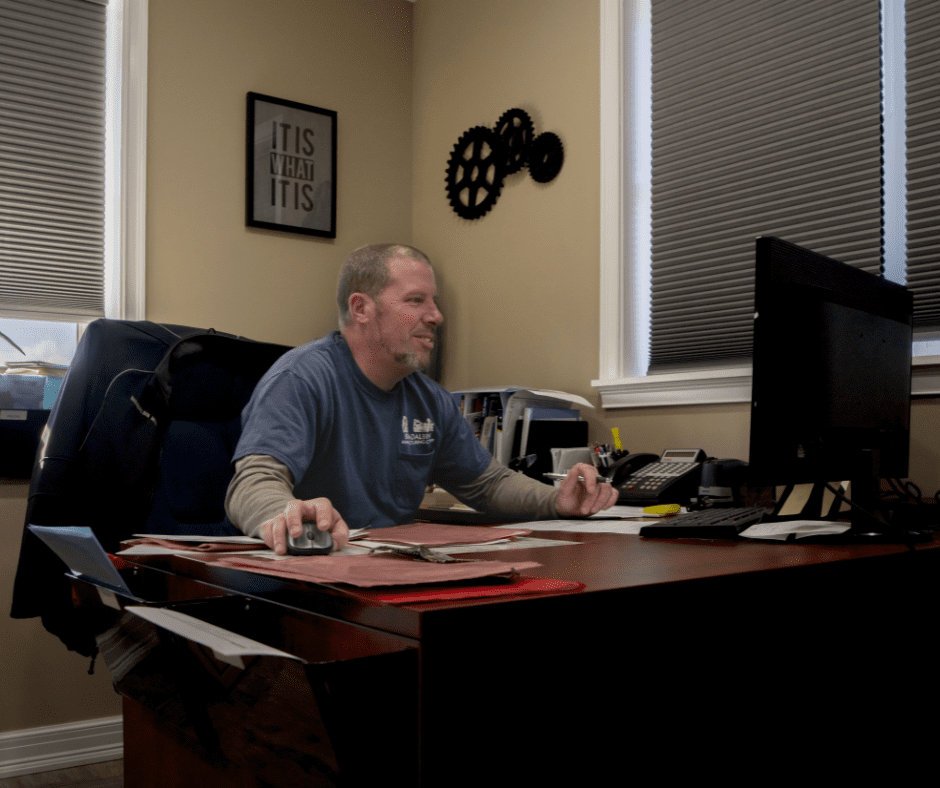

“Typically, everything we’re looking for is as soon as possible.” Bresney knows he can count on Broadalbin Manufacturing to complete the job quickly. It is not uncommon for Bresney to call shop foreman Ryan Sowle with an order that he needs the following day. “They really work with us on that speed and obviously high quality. They jump through hoops for us whenever we need something.”

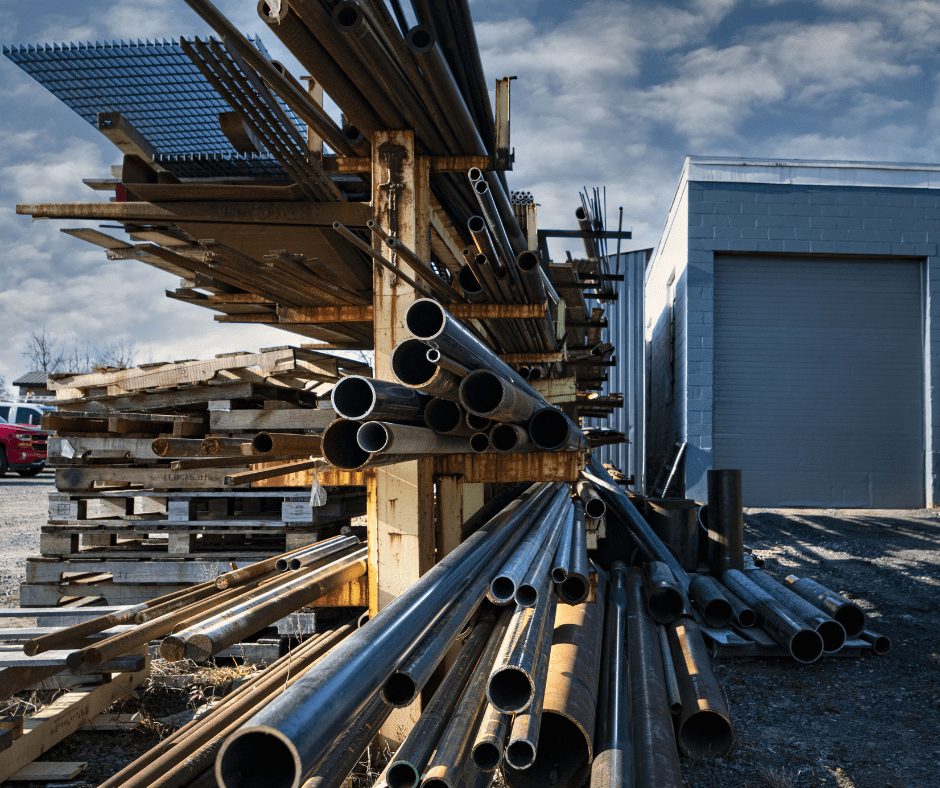

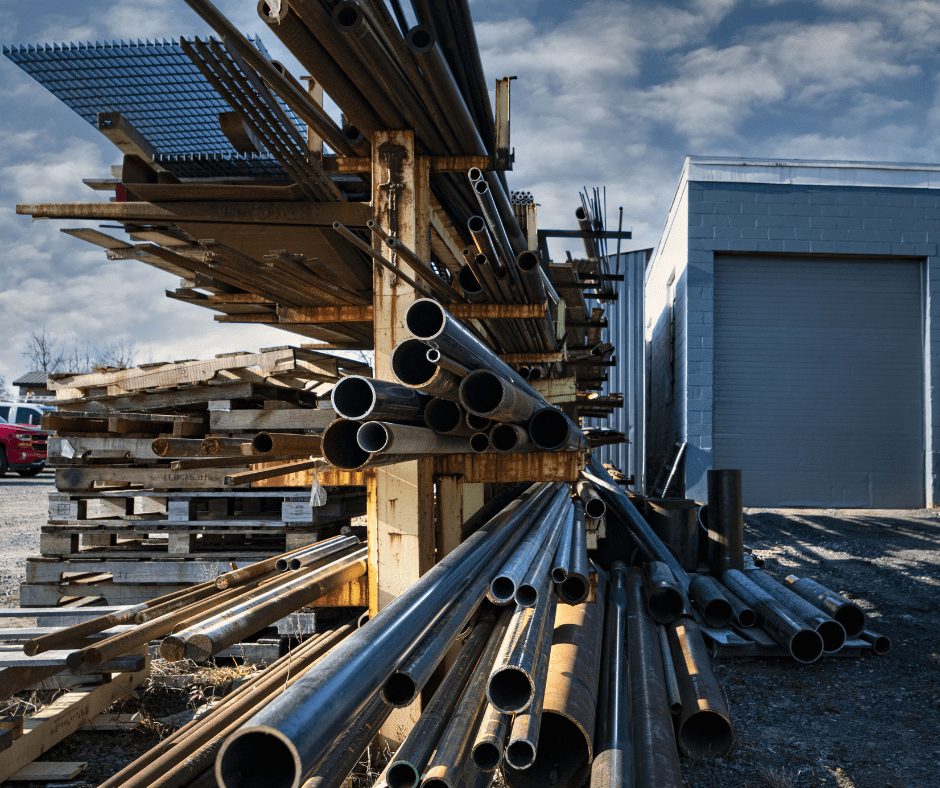

That level of service, expertise, and quality has kept Broadalbin Manufacturing’s business strong for the past 51 years. The company has a reputation for its tailor-made, precision metal fabrication work for all sizes of jobs for a wide variety of customers: commercial, governmental, and residential.

We do everything from taking care of local people that need steel

—any sort of work done as far as the fabrication of metal and machining, all the way up to General Electric.” Sowle said. For example, the firm crafted a rear bumper for a box truck for Skiff’s Dairy LCC in Johnstown. “If I need something made, they make it,” said Jim Skiff. “They can pretty much fabricate anything that you need for anything at a really reasonable price.” The company has crafted parts for snowmobiles, plow frames, patio furniture, gates, handrails and architectural metal pieces upon request, to name just a few items.

Sowle and the company’s 12 other machinists, welders, fabricators, and quality inspector can work from a customer’s rough sketches or make new pieces using the dimensions and design of an existing piece. When the Fulton County Sheriff’s Department wanted to replace the wooden box it used to house the agency’s sonar equipment with metal, they contracted with Broadalbin Manufacturing to do the job.

On the other end of the spectrum are large corporations like Plug Power and General Electric that use Broadalbin Manufacturing’s services for the manufacture of metal parts according to an engineer’s blueprints.

In addition to small custom jobs, Broadalbin Manufacturing also manufactures items in bulk according to customers’ specifications.

During the height of the COVID-19 pandemic, the company remodeled its 16,000 square-foot machine shop which houses a 1.75-inch-thick plasma cutter and computer-programmable fabrication equipment, among other items. For an added health and safety measure, they reconfigured the building’s interior so that the workers on the floor and office workers would have their own spaces and customers would have an office where they could collect their items. The exterior of the facility at 8 Pine Street also got a facelift. Broadalbin Manufacturing remained open for business during this time, as its services were deemed essential.

The firm trains its workers on the job, teaching them how to program the machines that do the actual cutting of metal.

Half of the company’s employees have been employed there for over 20 years. Sowle, who has been working at Broadalbin Manufacturing since 1993, is a prime example. “I graduated [from high school] on a Saturday morning and started here the following Monday not knowing a thing,” he said. “I learned through the years and worked my way up the ladder.”

Broadalbin Manufacturing’s investment in Sowle has paid off, as he clearly enjoys his work. “I love the everyday challenges,” Sowle said. “It’s different day to day. The thought of something that’s made by us that’s going to go halfway around the world and be used in a power plant, it’s amazing to me. It kind of makes you proud when you get done with it.” He also enjoys the business relationships he has made through the years with local business owners.

Broadalbin Manufacturing does its part to help the Fulton County community as well. Recently, it donated some metal bins it fabricated to the Girl Scouts. Sometimes, it hosts after hours tours for high school technology class students. New in 2021, the company brought in an intern from Broadalbin High School.

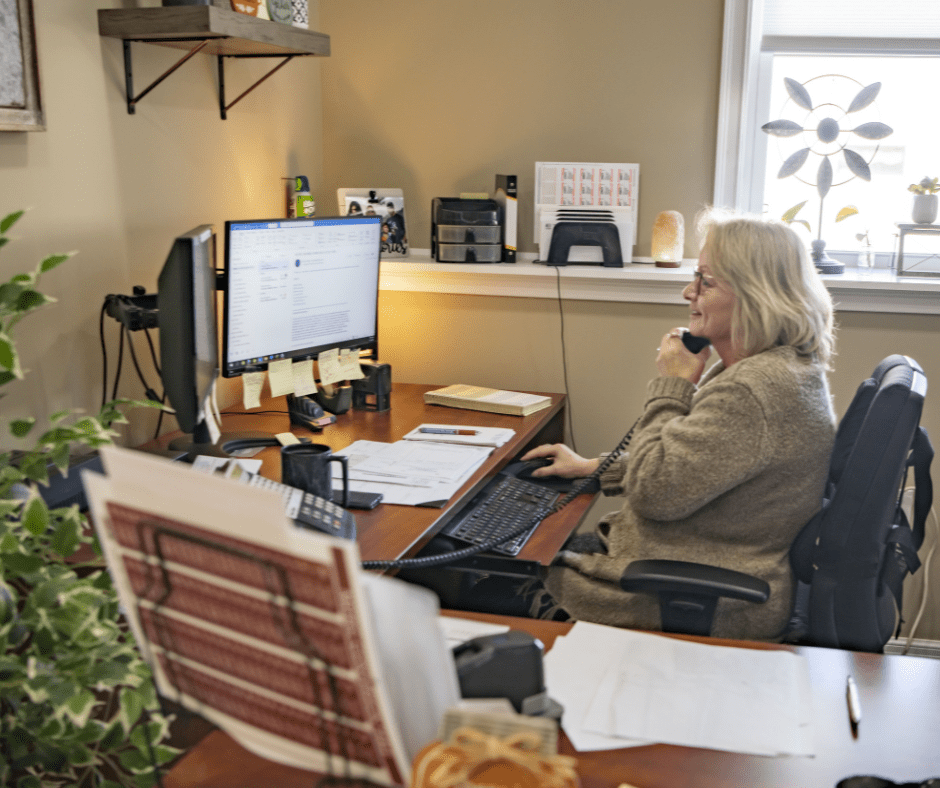

Michael Deuel purchased the company in 2004, and after his unexpected death in 2020, Deuel’s wife, Karen, took over the company. “Even through the tough loss of Michael, his wife is a really amazing woman,” Sowle said. “She’s taking the company to another level.”